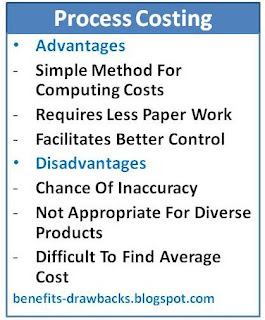

Merits Or Advantages Of Process Costing

The main advantages of process costing can be highlighted as follows:

1. Simple Method Of Costing

Process costing is very simple method of computing costs of each stage or process of production. Because of homogeneous products, average cost of product can be calculated easily in less time.

2. Periodic Calculation Of Cost

Cost of each process and per unit cost of finished products can be determined periodically at short intervals with less clerical and paper works.

3. Suitability

Process costing is suitable for standardized products, large scale production, identical or homogeneous products etc.

4. Better Managerial Control

Cost and performance of each process or department can be evaluated regularly at short intervals. With the help of standard costing, management can take appropriate steps to minimize unnecessary costs and wastage. So, process costing facilitates the management for better control.

Manufacturing firms can add or remove process as per their needs and requirements in order to control the cost of production. So, process costing facilitates flexibility in the production process.

Demerits Or Disadvantages Of Process Costing

The main disadvantages of process costing can be highlighted as follows:

1. Historical Value

This costing method uses historical or past cost data. So, it may not provide accurate cost information for better control.

Also Read:

Advantages And Disadvantages Of Activity Based Costing

Advantages And Disadvantages Of Job Order Costing

Advantages And Disadvantages Of Standard Costing

2. Inaccuracy

There exists a chance of inaccuracy or error while estimating the cost of work in progress or finished goods because it is based on average cost.

3. Unsuitability

Process costing is not suitable for diverse products. It is suitable only for identical products.

4. Difficulty In Average Cost

It is very difficult and complex to find out average cost if the company manufactures more than one type of products.