What Is Process Layout ?

Process or functional layout is an floor arrangement where machines and equipment of similar functions and processes are arranged in the same area. Similar types of machines and devices of each process are installed in the one floor or department. There are some benefits as well as limitations of process layout which are briefly discussed in this post.

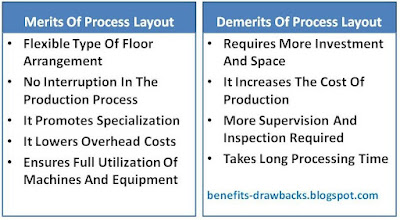

Benefits Or Advantages Of Process Layout

The main advantages of process layout can be highlighted as follows:

1. Flexibility

In process layout, changes and adjustment in operation can be made as per the requirement. So, it is more flexible than product layout.

2. Less Interruption

Another benefit of process layout is that it does not interrupt the production process because if there is a breakdown in one machine the work will be shifted to another machine because there are other machines to perform similar jobs.

3. Easy Expansion

If the company wants to increase its production capacity, more machines and devices can be installed without disturbing existing layout and operation process. So, it has high scope for expansion.

4. Requirement Of Less Investment

Process layout avoids duplication of machinery which is not possible in product layout structure. So, it requires less capital to acquire machines and equipment.

5. Optimum Utilization Of Machinery

In product layout, machines and devices are used for single product line, but in process layout, they can be operated in full capacity because they can be engaged in different operation. So, it ensures maximum utilization of fixed assets.

6. Promotes Specialization

It ensures specialization in manufacturing process by using automatic equipment and highly proficient workers.

7. Less Supervision

Because of automation and specialization, less supervision is needed in this layout.

Drawbacks Or Disadvantages Of Process Layout

The main disadvantages of process layout can be described as follows:

1. More Cost Required

In process layout, equipment are arranged according to their functions. Similar machines are grouped in one floor. It increases the movement of materials from one process to another which increases the cost of materials handling. It also increases the chance of wastage because of intermittent flow of materials. So, it requires more cost of production than product layout.

Also Read:

Advantages And Disadvantages Of Product Layout

Difference Between Product And Process layout

2. More Floor Space

It requires more space to arrange machines and equipment. Separate floor space is required for the installation of different types of machines. So, it lacks optimum utilization of space in the production center.

3. Long Processing Time

Manufacturing process takes more time because of more movement of materials from one department to another. So, it is more time taking layout than product layout.

4. High Cost Of Production

Due to more material handling costs , wastage and slow production process, it increases the cost of production.

5. More Inspection And Supervision

It requires more inspection because each department should handle variety of jobs. It also requires strict supervision to control inventory.

Pros

- It is flexible and can be easily expanded as per the requirement

- There will be no stoppage in the production process

- Less supervision and control is required because of specialization

- It fully utilizes the machines, equipment and devices in the work station

- It minimizes the overhead costs

Cons:

- It requires more investment

- More space is needed to arrange machines and equipment

- Due to long processing time, cost of production will be increased

- It requires more inspection costs than product layout