What Is ABC Analysis Method Of Inventory ?

ABC analysis of a technique of categorizing the inventory or materials according to their value and importance. Highly valued items are categorized in class 'A' , least valued materials in class 'C' and less profitable items than 'A' and more profitable than 'C' fall in class 'B'. A strict control is required for highly important and profitable items (group A materials). Average control is exercised for group B and least control is exercised for group C inventory.

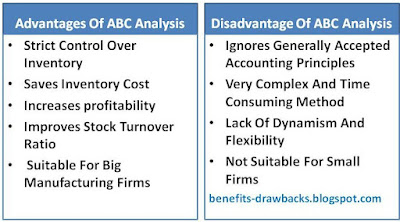

Benefits Or Advantages Of ABC Analysis

The main advantages of ABC inventory analysis can be highlighted as follows:

1. Better Control Over Inventory

ABC analysis system of inventory management gives focus on the control of high priority products (inventory categorized in group A). Strict control over such materials helps to minimize wastage and misuse of most valuable items.

2. Provides Views

It provides up-to-date information about the quantity and value of stock. It helps the management for decision making and forecasting.

3. Saves Cost

Because of strict control and minimization of wastage, it helps to reduce inventory cost. Materials that falls in group A or high valued products are purchase in less volume which helps to decrease material purchase, handling and storage costs.

4. Better Stock Turnover

Better control, cost reduction and waste minimization leads to increase in stock turnover ratio of the firm.

5. Effective Cycle Counting

ABC analysis provides accurate data about the inventory fluctuations which helps the manager in cycle counting.

6. Economical System Of Inventory

It is more economical than others techniques of inventory management because it does not spend more cost and effort for those materials which are grouped in B and C category.

7. More Profit

Proper classification of inventory, better handling and cost reduction helps to increase the profitability of the firm.

8. Suitable For Big Firms

ABC analysis system is suitable for big business companies which consumes different types of materials in larger volume.

The main disadvantages of ABC analysis system of inventory management can be highlighted as follows:

1. It Ignores GAAP

This method does not follow the rules of GAAP (generally accepted accounting principles). Therefore, it is suitable for internal use only.

2. Complex And Time Consuming

It is very complicated task to categorize materials in different groups. It consumes more resources such as time, labor and cost to group materials in case of large group of inventory.

3. Static In Nature

Value of materials may change according to the market trend. It means category A product may move to B and C may move to A with the change in dollar value of product in the market. In such situation, ABC inventory system may become outdated because of the lack of dynamism.

4. Based On Financial Value

This analysis is based completely on the dollar value of materials and does not consider other important factors.

5. Not Suitable For

ABC analysis is not suitable for small business houses which does not require large volume of inventories. It is also not applicable for materials which cannot be standardized.

6. Possibility Of Loss

It gives less attention to B and C grouped materials. Therefore, there is a chance of loss because of over stock, damage and wastage of these items.

Pros And Cons Of ABC Analysis In Short:

Pros:

- It ensures better control of inventory by minimizing wastage and improper use of materials

- It is suitable for big manufacturing companies

- It improves stock turnover ratio

- It saves time and cost to store materials

- Because of effective control and proper utilization of materials, reduction in time and cost, it helps to improve the profitability of the business.

Cons:

- It is complex than other techniques of inventory control

- It lacks dynamism and flexibility

- It is not suitable for small firms because it consumes high resources

- It ignores GAAP